Air Filter

Air-filtersClean intake air is important for problem-free driving. But there are still particles, soot, fine dust, etc. Dirt such as dirt is taken in with the air. Result: dust particles enter the combustion chamber, causing scratches and premature wear in the engine. Electronic parts in the intake system before the combustion chamber, such as sensors, may malfunction or even malfunction.

Filter materials of air filters must have high durability. It is important that it filters the intake air efficiently and reliably. Thus, the air/fuel mixture is formed in the calculated ratio and engine performance is ensured to be constantly high.

Increasingly advanced technologies and systems in engine design, the ever-increasing number of parts and engines, as well as stricter legal regulations regarding vehicle safety and occupant protection, are constantly reducing the assembly space within the engine compartment. Therefore, to meet increasing demands and accommodate shrinking installation spaces, modern air filter systems must be more compact.

Fuel Filter

fuel-filtersThe most basic requirement for problem-free engine operation is clean fuel. Fuel comes to the injection system or carburetor through the fuel pump. Particularly in modern injection systems, dirt particles cause increased wear. Water in fuel can also cause serious damage by causing corrosion. At worst, it can cause complete damage to the injection system, stopping the vehicle. Wear in the injection system or carburettor leads to a significant increase in fuel consumption and irregular engine performance.

Modern injection systems such as common rail or pump injector require innovative solutions tailored to new technologies.

Fuel filter types

Fuel Filter Elements: Replaceable and housed in a separate housing integrated into the engine:

- Fuel filter elements are made of paper or felt filter material in a housing in accordance with DIN (Deutsches Institut für Normung - German Standards Institute) standards. - They are installed by screwing in the middle. - Special filter shapes are available.

Atom Fuel Filters: The housing and filter element are a single unit. During the replacement, the entire unit is replaced with a new one in one piece. There are different types of atomic filters:

- Standard atomic fuel filters, - Version with water discharge facility, - Types with specially shaped ports, - Special types connected to the water level indicator.

Fuel Line Filters (In-Line): These filters are mounted serially on the fuel line. The housing and filter element are completely replaced during replacement.

- Plastic inline fuel filters, - Metal inline fuel filters.

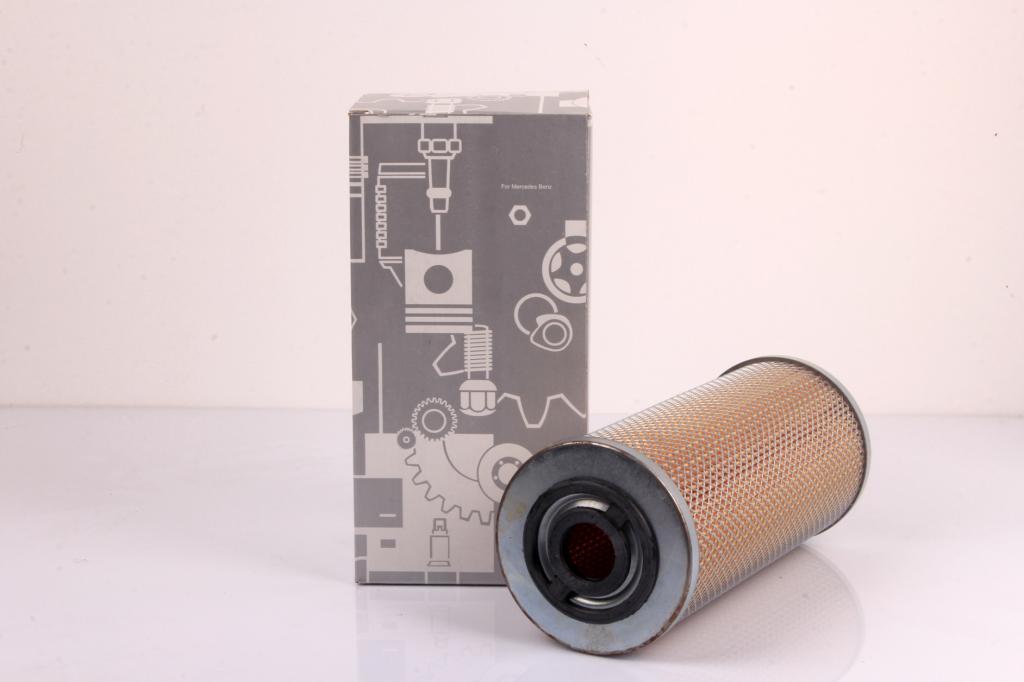

Oil filter

Oil filters, Engine oil lubricates all functional parts that move within the engine.

High engine performance and low fuel consumption place very high expectations on engine manufacturers. Only clean oil can ensure consistent engine performance. As a result of combustion, various dirt and combustion waste particles, such as soot, are mixed into the engine oil. These contaminate the oil and reduce its fluidity. In this case, the oil cannot do its job fully and, in particular, its corrosion protection function is reduced. As a result, engine performance decreases and fuel consumption increases. In the worst case scenario, the engine will be damaged.

The oil filter must be replaced in a timely manner. If the oil filter is changed regularly, only clean oil will circulate in the system. This greatly increases engine efficiency and provides reliable protection against wear.

Since oil filters have to meet different requirements in various areas, they can take various forms:

Oil Filter Elements: Oil filter elements are either placed in their own housing or directly integrated into the engine lubrication system. In this case, it is especially more environmentally friendly since only the filter element is replaced. The housing and valves remain on the engine block. The exact placement of the oil filter elements into the housing ensures that the filters are completely sealed.

Atomic Oil Filters: Atomic oil filters form a single-piece unit containing the body and filter element. The entire unit is replaced during maintenance. The following parts can be integrated:

- One-Way Valve: It prevents the oil in the oil channels and filter from flowing back to the crankcase when the engine is stopped and ensures that there is oil in the channels when the engine is started.

- Bypass Valve: It allows the oil to go to the channels in case of a sudden increase in oil pressure when the engine is started cold or if the oil filter becomes clogged for any reason, such as exceeding the maintenance interval.

- Removal and Installation Slots: Allows you to quickly and effectively remove and install the oil filter with removal and installation tools.

Special Designs; Like Transmission Filters

Main Flow Filter: Main flow filters are placed in the circulation system, all the oil that needs to be cleaned reaches the system after passing through the filter.

Combined Main and Auxiliary Flow Filters: 90-95% of the oil is transmitted to the system through the star-shaped folded filter of the main flow filter, and 5-10% through the bypass filter or centrifugal filter that moves with oil pressure. Thus, precise and sensitive filtering is achieved.

High levels of soot particles in diesel engines reduce the quality of engine oil. As the oil becomes dirtier, its viscosity increases (its fluidity decreases) and it becomes less effective. Contaminated lubricating oil increases engine wear and reduces engine life. Since excessively used oil cannot provide sufficient lubrication, possible damage to the bearings cannot be prevented. Auxiliary flow filters are important to cope with increased soot content in the lubricating oil and at the same time extend maintenance intervals. In the bypass system, 5-10% of the lubricating oil passes through very fine unprocessed cotton material or paper material or is filtered by a centrifugal filter that has a motor made of steel and/or plastic and moves with oil pressure. This reduces the amount of soot in the oil circuit.

Depending on centrifugal filter size, oil pressure and viscosity, it reaches speeds of more than 10,000 cycles. The centrifugal filter processes approximately 10% of the oil. It efficiently separates particles of all sizes that have a density greater than the lubricating oil. This means that it can separate soot particles smaller than one thousandth of a millimeter from oil.

Cabin Filter cabin-filtersIn residential centers, there are large amounts of dust, pollen, soot and other pollutant particles in the atmospheric air, as well as many gas molecules that are harmful to health. An increasing number of people complaining about allergic reactions have begun to attach great importance to air conditioning and cabin filters. For this reason, many vehicles produced today have cabin filters. Cabin filters filter pollens, other unwanted particles and harmful gases from the air and allow cleaner and higher quality air to enter the vehicle. This is especially important for people with allergies, asthma patients and children.

cabin-filtersIn residential centers, there are large amounts of dust, pollen, soot and other pollutant particles in the atmospheric air, as well as many gas molecules that are harmful to health. An increasing number of people complaining about allergic reactions have begun to attach great importance to air conditioning and cabin filters. For this reason, many vehicles produced today have cabin filters. Cabin filters filter pollens, other unwanted particles and harmful gases from the air and allow cleaner and higher quality air to enter the vehicle. This is especially important for people with allergies, asthma patients and children.

There are two types of cabin filters:

Particle Filter: Particle filters keep dust and dirt particles such as pollen, diesel soot and tire particles out of the vehicle cabin. The most critical point in this regard is that cabin filters are expected to achieve the highest possible filtration performance in the narrow space where they are installed. For this purpose, a cabin filter with high quality and high filtration technology should be used.

Carbon Cabin Filter: Carbon filters have an additional function in addition to particulate filters. Activated carbon layers placed between non-woven fiber materials absorb harmful gases like a sponge. These gases are 10,000 times smaller than a human hair. Nitrogen oxides, fuel vapors and ozone molecules are some of these harmful gases. Therefore, carbon filters ensure a healthy atmosphere inside the vehicle. The structure of these modern filters includes non-woven fiber layers, active carbon layers, as well as carrier material layers to increase durability.

]

]