Structure Working and Parts of Power Steering System

Power steering is one of the most widely used steering assist systems. It is based on the use of hydraulic oil pressure to turn the steering wheel more easily. In new generation passenger vehicles, hydraulic steering is gradually being replaced by the electric steering system.

The power steering system can be applied to both “pinion rack and pinion gearbox” and “worm ball type gearbox”. Here, the hydraulic pinion-rack steering system will be taken as the basis.

For more information and the main topic (See: Steering System Types and Structure)

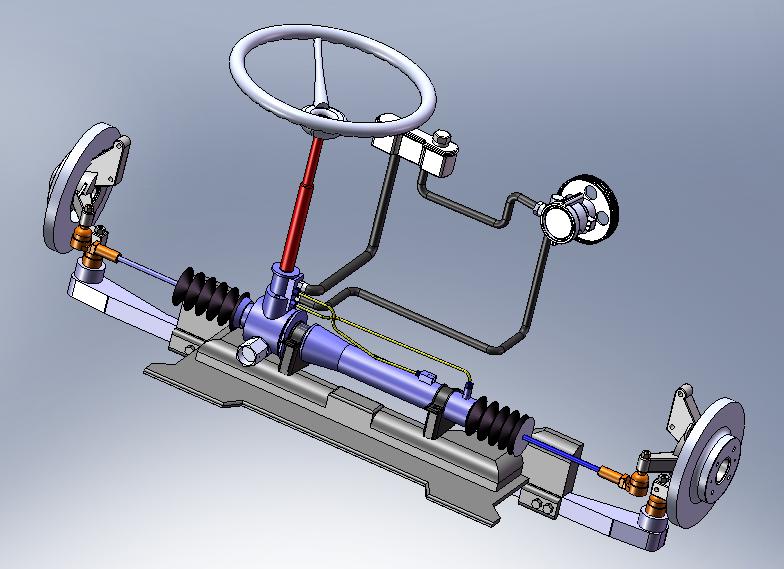

Parts of Power Steering System

*Steering wheel

*Steering shaft and column

*Hydraulic Valve unit (between steering shaft and pinion gear)

*Steering gear box

*Hydraulic cylinder

*Hydraulic pump

*Hydraulic oil box (reservoir)

*Connection pipes and hoses

Working Principle of Power Steering System

In power steering, the relationship between pressure and force is used. The force obtained from hydraulic pressure contributes as an additional force to the force applied when the steering wheel is turned. It does not operate the system alone, therefore it is an "auxiliary system". The hydraulic pressure in the system is converted into thrust force by the bi-directional piston in the hydraulic cylinder in the steering box, providing additional force to turn the steering wheel. As the steering wheel softens, the steering force acting on the wheels increases.

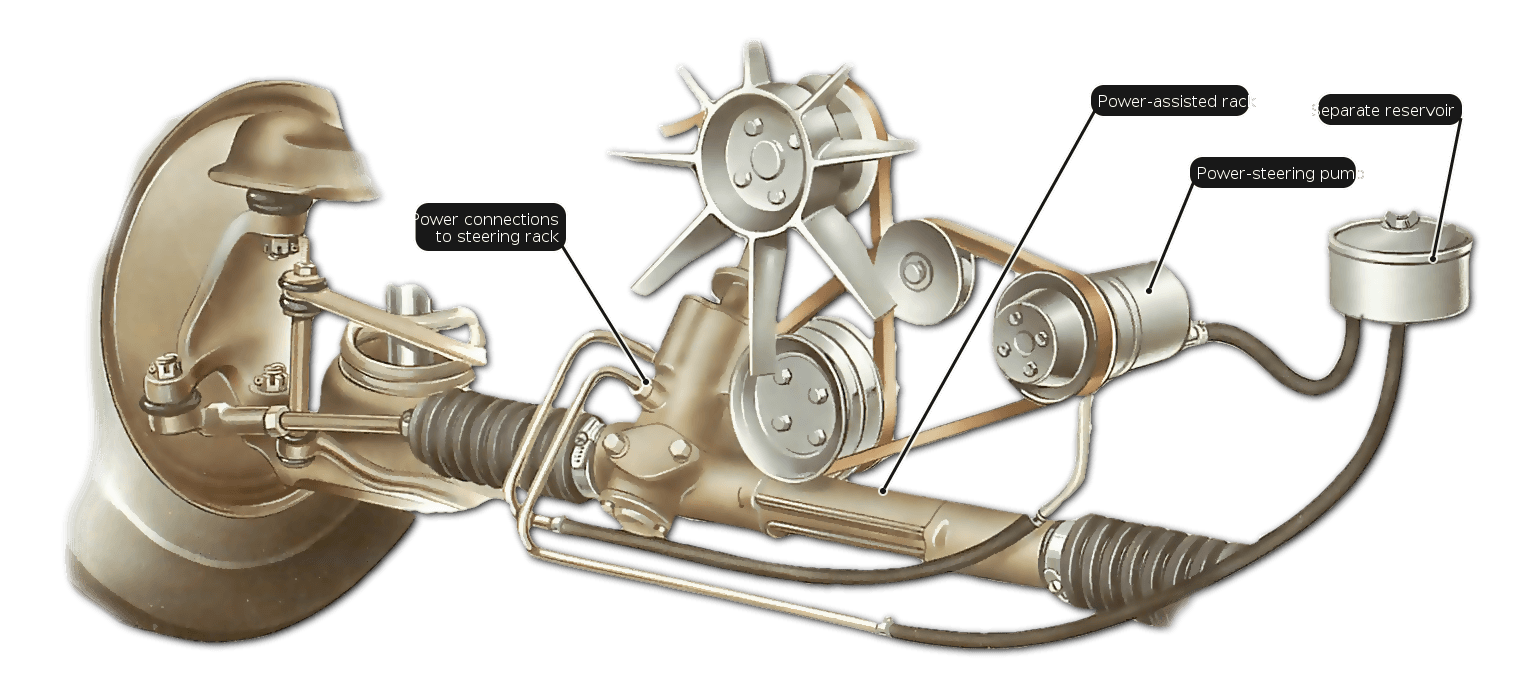

Hydraulic pressure is created in the steering hydraulic pump. The pump receives its movement from the engine via belt-pulley and converts this movement energy into hydraulic pressure and sends it to the control valve (rotary control valve).

The oil required by the hydraulic pump and system is stored in the hydraulic oil box (reservoir). Additionally, the oil returning from the system drains into the tank.

The pressurized oil coming from the pump is directed to the hydraulic cylinder through the control valve (rotary valve) located in the steering box. There are two lines between the control valve and the hydraulic cylinder. These two lines are separately connected to the two pressure chambers of the cylinder so that the cylinder piston operates in the right and left directions. The control valve determines which line the pressurized hydraulic oil will be sent to, depending on the direction of rotation of the steering wheel. When the steering wheel is straight (not turned), the oil sent by the pump to the control valve is directed back to the tank, so the pressurized oil has no effect.

There is a hydraulic cylinder in the gearbox body, there is a bidirectional working piston inside the hydraulic cylinder, the movement of the piston is determined according to the direction of application of oil pressure. The end of the piston rod is connected to the rack, the end of the rack is connected to the long tie rod, the long tie rod guides the short tie rod, and the short tie rod guides the tie rod end and the axle carrier (wheel).

The hydraulic system works according to the "Pascal principle". In order to increase the force, the pressure or the piston surface area must increase. The force produced by the system depends on the amount of hydraulic pressure, high pressure; It creates more force on the piston inside the cylinder, thus increasing the force acting on the wheels and making the steering softer.

Effects That Make It Difficult to Turn the Steering Wheel in the Vehicle

*Low speed or vehicle stalling. When the vehicle is stationary or driving very slowly, the force required to turn the steering wheel increases greatly, this is due to the friction of the tire with the ground; It has an adverse effect on the steering wheel. As the speed increases, the force required to turn the steering wheel decreases. For example, in vehicles with mechanical steering, it can be observed that the steering wheel softens when the vehicle starts to walk. In this regard, in a steering system, additional equipment (hydraulic or electric steering) is most necessary and functional at low speeds and when the vehicle is stationary (e.g. parking).

*Vehicle weight or loading. The high weight of the vehicle is one of the most important factors that increases the force required to turn the steering wheel. Especially in commercial vehicles carrying loads, the load on the wheels is very high, in which case it will be very difficult to turn the steering wheel. The reason of this; The friction force between the tire and the road is determined by the vertical force (weight) applied to the ground and the friction coefficient. As the weight increases, friction increases, the magnitude of the reverse moment during steering of the tire increases, and it becomes more difficult to turn the steering wheel.

*Using wide tires. Wider tires make steering more difficult.

*The steering wheel is small in diameter. As the steering diameter decreases, the force required to turn the steering wheel increases, because the moment, which is the effect that rotates the steering shaft, consists of the product of force and radius.

Duties of the Power Steering System

*Soft steering and comfortable driving. It enables the steering wheel to be turned comfortably and smoothly, especially when parking and at low speeds, it becomes heavy (difficult to turn). In other words, it softens the steering by producing great power at low speeds.

*As speed increases, boost power decreases. As the speed of the vehicle increases, the force required to turn the steering wheel will decrease, and at high speeds the steering maneuver becomes very less. For this reason, as the speed (some are sensitive to revolutions) increases, the support of the hydraulic steering system decreases and the steering becomes harder.

*It prevents the steering wheel from deflecting due to impacts from the road to the wheels, but at the same time it must provide a good driving (steering) feeling for the driver to perceive road reactions. Thus, driving - maneuvering performance and safety are improved. If the assist power of the power steering is too high, the driving feeling will decrease.

*It is activated quickly and sensitively when the steering wheel moves, the driver does not feel it.

If the Power Steering System is Disabled

Even if the power steering assist is disabled, it is still possible to use the steering system and steer the vehicle, it will just be quite difficult to turn the steering wheel. Equipment that strengthens the steering systems (hydraulic-electric) does not interrupt the mechanical connection between the steering wheel and the wheels. The reason for this is for safety reasons. In case of malfunction, the steering of the vehicle must be ensured.

In heavy commercial vehicles (trucks, etc.), since the load is too high, it will be impossible to turn the steering wheel if the power steering is disabled; To avoid this situation, a double hydraulic steering circuit is used in these vehicles, and if the main system fails, the backup hydraulic system is activated.

]

]